Researchers from a German national laboratory, the Physikalisch-Technische Bundesanstalt (PTB) have collaborated with Fellow Jun Ye, Visiting Fellow Lisheng Chen (Wuhan Institute of Physics and Mathematics, Chinese Academy of Sciences), and graduate student Mike Martin to come up with a clever approach to reducing heat-related “noise” in interferometers. Interferometers are widely used measurement tools in optical atomic clocks, astronomy, and spectroscopy. Their thermal noise is due to incoherent collective motions of atoms and molecules inside them (and other material systems). Motion-related noise increases as the temperature goes up.

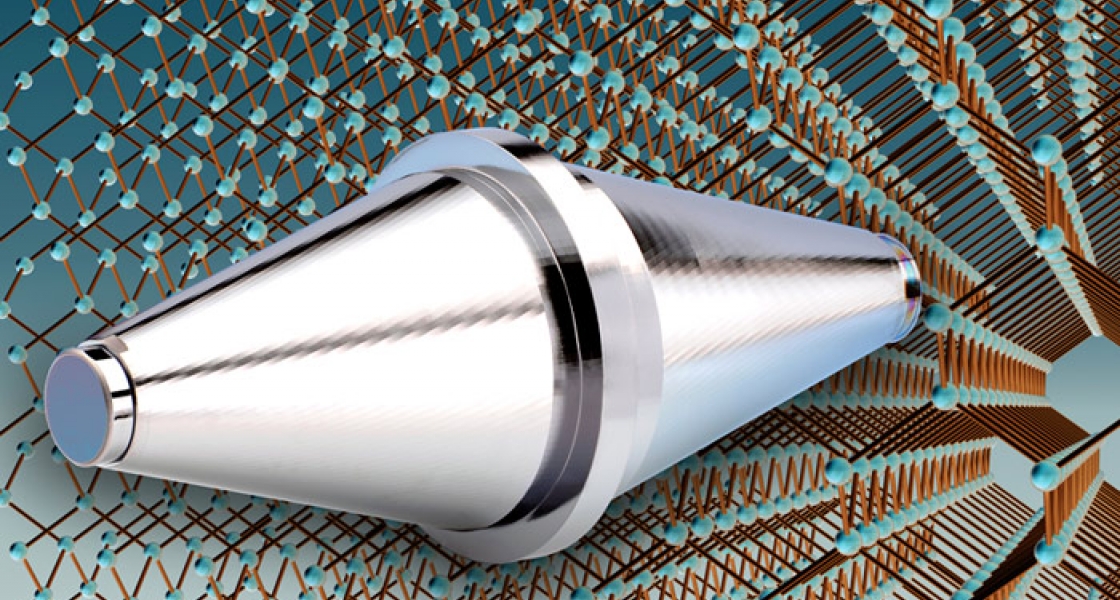

To reduce this noise, researchers designed an optical cavity made from a single crystal of silicon. An ultrastable laser system using such a cavity could theoretically have nearly ten times less heat-related noise than other ultrastable optical cavities used to stabilize laser frequencies.

Since 2008, graduate student Mike Martin, former graduate student Marty Boyd, Chen, and Ye have all worked with PTB on testing and comparing a laser using the new silicon crystal cavity with one of the best Ye group lasers, which uses a spacer made of ultralow expansion glass and mirror substrates made from fused-silica glass.

The new cavity’s spacer and mirrors are made of single crystal silicon and operated at 124 K, a special temperature at which a silicon crystal’s heat-related expansion is at a minimum. The cavity itself is mounted vertically in a way that is immune to additional vibrations in the surrounding environment. Only the mirror coatings contribute in a significant way to the thermal noise of the new silicon cavity system.

Recently, a laser using the new cavity was tested and compared with two ultrastable lasers, including one Martin brought to Germany from the Ye labs. All three lasers are extremely stable. For instance, both the new silicon-cavity laser and the laser from JILA can remain coherent (in sync) for distances of up to three million kilometers.

The three lasers were tested in a “three-cornered hat” comparison. In this kind of comparison, performance differences are measured between laser 1 and 2, laser 2 and 3, and laser 3 and 1. Laser 1 was a built at PTB using a cavity made of ultralow expansion glass. Laser 2 was built at JILA. It uses a fiber laser stabilized to an ultralow-expansion-glass cavity and fused-silica mirrors. Laser 3 was stabilized to the ultrastable cavity made of single crystal silicon.

The tests revealed that the performance of the laser with the single-crystal silicon cavity was better than the two comparison lasers, although not yet as good as is theoretically possible. However, PTB and JILA scientists expect to be able to make further progress in improving the single-crystal silicon cavity’s performance in precision metrology. A new laser using the cavity will soon become the clock laser for optical atomic clocks under development at PTB. A second system will soon come to JILA for use in the strontium optical lattice clocks in the Ye labs.

The Physics Frontiers Centers (PFC) program supports university-based centers and institutes where the collective efforts of a larger group of individuals can enable transformational advances in the most promising research areas. The program is designed to foster major breakthroughs at the intellectual frontiers of physics by providing needed resources such as combinations of talents, skills, disciplines, and/or specialized infrastructure, not usually available to individual investigators or small groups, in an environment in which the collective efforts of the larger group can be shown to be seminal to promoting significant progress in the science and the education of students. PFCs also include creative, substantive activities aimed at enhancing education, broadening participation of traditionally underrepresented groups, and outreach to the scientific community and general public.

The Physics Frontiers Centers (PFC) program supports university-based centers and institutes where the collective efforts of a larger group of individuals can enable transformational advances in the most promising research areas. The program is designed to foster major breakthroughs at the intellectual frontiers of physics by providing needed resources such as combinations of talents, skills, disciplines, and/or specialized infrastructure, not usually available to individual investigators or small groups, in an environment in which the collective efforts of the larger group can be shown to be seminal to promoting significant progress in the science and the education of students. PFCs also include creative, substantive activities aimed at enhancing education, broadening participation of traditionally underrepresented groups, and outreach to the scientific community and general public.